Turning & Machining

Ideas are always first created in the head and are being visualized when the design is right, for example with CNC machines or lathes, and transformed into a three-dimensional shape.

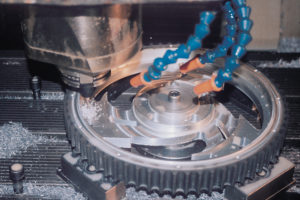

Other than bending and forging, turning and machining is metal forming that creates tension. That may sound simple, but it isn’t. At Rick’s Motorcycles we use modern turning and CNC machining equipment, which is able to bring the metal into the desired shape with a precision of within 1/100 mm. Modern CNC programs, which are sent to the machines by the constructors, ensure that within the shortest time a new product is created? That is a vision that also Rick’s Motorcycles has, but it is not as easy as it sounds. What looked perfect on the monitor does not necessarily conform to the visions of the designers in a three-dimensional form. Often it is a long process until a sellable custom part has been created, which can then be produced with CNC equipment in small quantities.

At Rick’s highly qualified tool makers, turners and machining experts occupy themselves with getting the machines ready. So that these can work precisely, it is vital to determine the suitable raw material and set it up correctly. Every machine can only function if it has been equipped with the right tools beforehand as each machine has to be fitted with previously determined tools depending on the product to be machined.

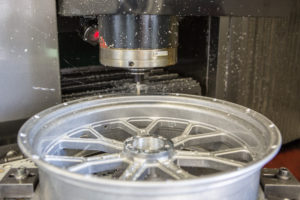

Layer by layer, tenth millimetre by tenth millimetre a new shiny custom part is created from an unremarkable block of metal. The creation of one of Rick’s typical design wheels can take hours. Especially with wheels it is more difficult as exclusively high tensile forged aluminium is used. The raw material displays, by nature, already material tension, and the wrong treatment could lead to it chipping when tensioning, thereby influencing later shape negatively.

Rick’s has been making wheels for more than a quarter of a century, and despite this, every forged wheel made in the CNC machines is still a challenge to our specialists. In the end no product leaves the company that does not correspond to our high quality standards.